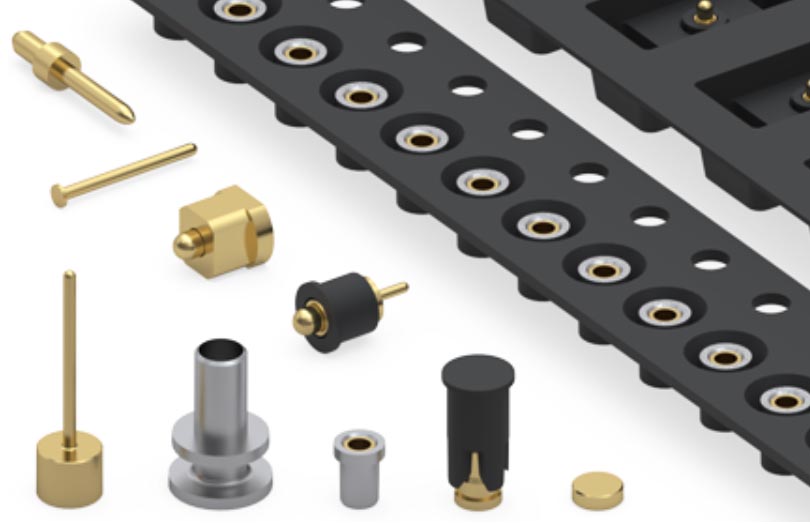

VALUE-ADDED CAPABILITIES

About Our Value-Added Capabilities

Whatever your project, DW Products can supply you with complete turnkey parts, utilizing our extensive machining capabilities. Our team goes beyond just CNC-machined parts — machining turnkey parts by offering a range of supporting services and options throughout the process to ensure you receive an optimal final product. We go beyond exceptional precision to deliver comprehensive project management and world-class customer service and care. As part of our additional screw machining capabilities, we can help with materials procurement, value added machining, heat treat, metal finishing, packaging and inventory management.

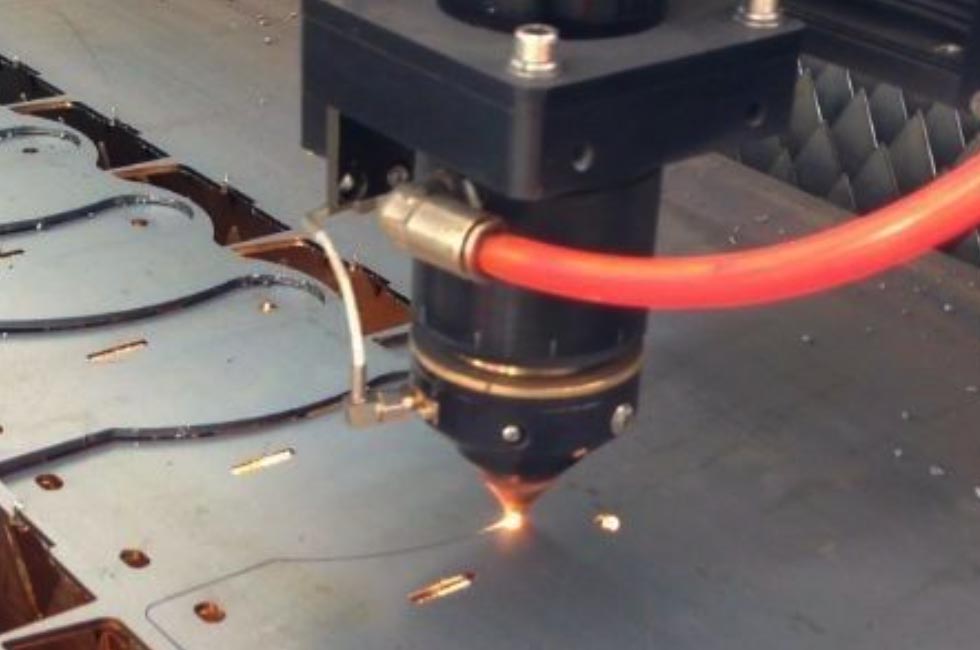

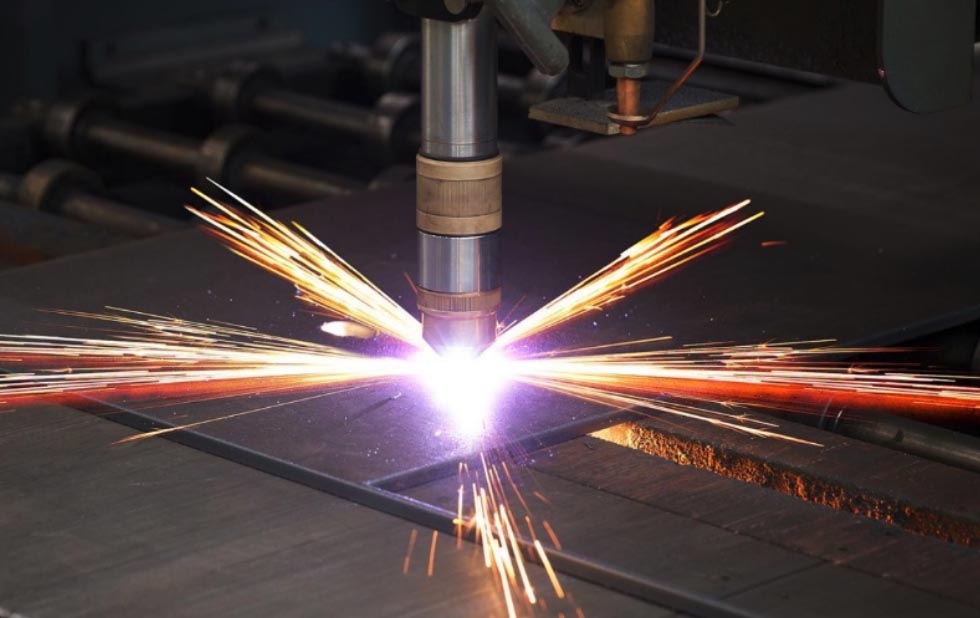

Metal Fabrication

Metal fabrication services involve using different equipment and tools to transform raw materials into structures and machines through various processes, including cutting, machining, forming, welding, burning and final assembly. DW Products provides complete metal fabrication for CNC parts with a talented team of specialists. Among our services, you’ll find:

- Forming

- Press brake

- Welding

- Laser and waterjet cutting

- Powder metal (sintered hubs and filter elements)

Kitting and assembly services are available through our partnership customer and supplier networks.

Material Options

At DW Products, we know no two projects are alike. When you’re creating a specific part, the raw materials you select matter for functionality, performance and durability.

We’re proud to offer numerous material options for your precision parts. When you partner with us, you can choose from:

- Brass

- Copper

- Bronze

- Aluminum Alloys (6061, 2011 and 2024)

- CF (cold finish) Low Carbon Steels (1018, 1215 and 12L14)

- CF Alloy Steels (4140/42 and 8620)

- Higher Carbon Steels (1045, A311 StressProof, FatigueProof, 1117, 1141, 1137 and 1144)

- Titanium

- Stainless Steels (303, 304, 316, 416 and 17-4)

- Plastics (polycarbonate, Delrin, PTFE, nylon and nylon blends)

DW Products works with 12′ long solid bars in round, hex or square shapes as well as DOM, EW and seamless tubing.

Metal Finishing

As the final step of the manufacturing process, metal finishing procurement options can add to your parts’ visual appeal or provide extra protection, performance and durability. These processes can also help prepare the surface for any final coatings you select. DW Products handles CNC metal finishing of parts with techniques including:

- Electroplating

- Electroless plating

- Anodizing

- Painting

- Powder coating

- Dip/spin and spray coating

We also proudly offer CNC parts cleaning, including:

- Ultrasonic part cleaning

- Aqueous part cleaning

- Vapor degreasing

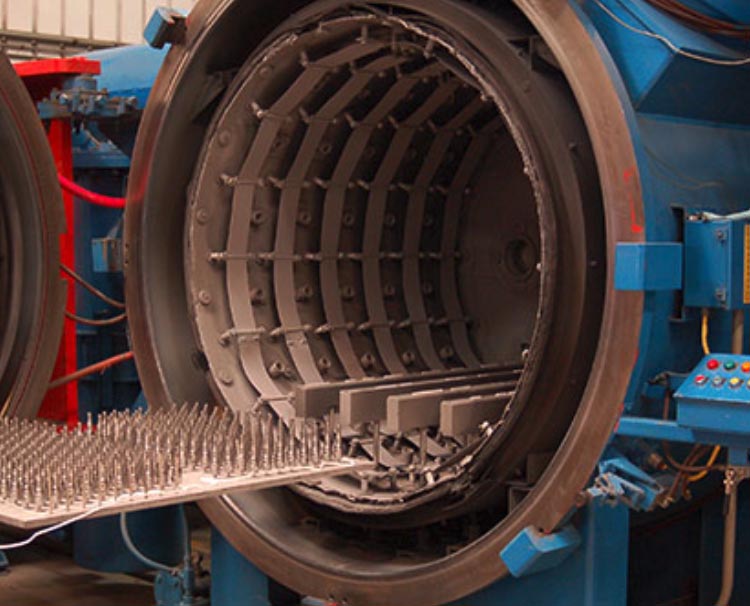

Heat Treating Parts

Heat treatment appears in different stages of the manufacturing process and introduces specific temperatures to alter existing material properties. When the operation is performed correctly, CNC heat-treated parts can better resist wear and tear because they undergo changes that make them harder, tougher or otherwise more suited to the application for which they’re intended.

DW Products provides a range of heat treatments, including carburize, carbonitride, stress relieve, annealing and selective induction.

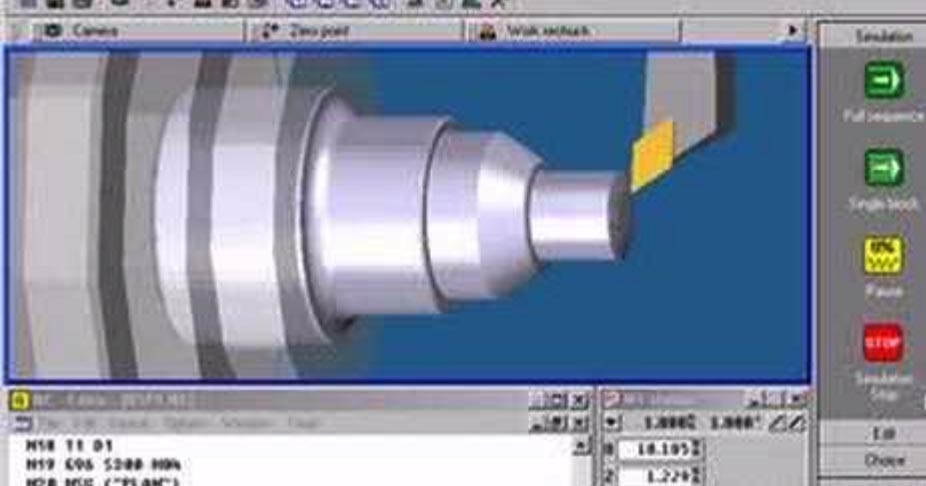

Extensive Machine List

At DW Products, we boast an extensive machine list and CNC specialists to support our robust capabilities, allowing us to manufacture a large assortment of parts and complete high-volume runs. For our customers, it means a versatile and experienced partner with short turnaround times.

Product Design Support

We’re leaders in CNC-machined product design, and we have the equipment, resources and expertise you need to make your project a success. DW Products offers product design support services, including swift and affordable production of prototypes and pre-production sample parts. Ensuring our clients receive turnkey machining and turnkey components.

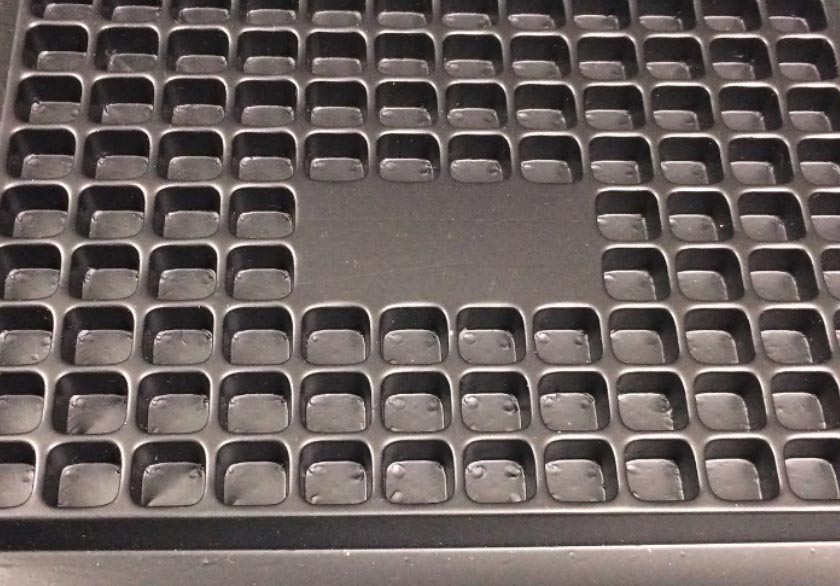

Packaging Options Available

Once your parts are complete, we can handle the packaging to help you protect and monitor the order throughout its inventory journey. We have numerous packaging options available, including:

- Cell

- Stacked/layered tray

- Tube

- Tape and reel

- Bagged/tagged

- Loose piece

- Bulk poly bagged and boxed

- Barcoding

- Special labeling

Inventory Management

No matter which inventory management method works best for your business, DW Products can help. We offer:

- Ship-To-Dock

- KanBan

- Just-In-Time (JIT)

- Consignment

- Stocking distributor services

The materials and services we provide will always have chemical and process certifications. Lot traceability is also standard practice.

Comprehensive Project Management

When you partner with us, you get experienced and comprehensive project management from our team of specialists to help make your project a success. DW Products is with you from start to finish and will always have an open and up-to-date communication stream with our customers.

Exceptional World-Class Customer Service and Care

At DW Products, we strive to be responsive to our customers and provide individualized attention to each project we undertake. We’re an ISO 9001:2015-certified organization committed to premium quality and short lead times.

Discover the DW Products difference by requesting your quote or connecting with a team member for assistance. Call (866) 366-8455 today to get started!

GET A FREE PROJECT QUOTE!

WHAT DW PRODUCTS CUSTOMERS CAN EXPECT

-

EXCELLENCE

-

INNOVATION

-

ACCOUNTABILITY

-

RESPECT

-

INTEGRITY

-

SERVICE

-

QUALITY

-

DELIVERY

-

VALUE

-

CONTINUOUS IMPROVEMENT

WHAT DW CUSTOMERS CAN EXPECT

-

EXCELLENCE

-

INNOVATION

-

ACCOUNTABILITY

-

RESPECT

-

INTEGRITY

-

SERVICE

-

QUALITY

-

DELIVERY

-

VALUE

-

CONTINUOUS IMPROVEMENT